BPI-Cyclone Air Purification System中文

The task of air purification is to remove suspended particles in the air (such as PM2.5, bacteria, viruses, etc.) and purify harmful gases (such as VOC, formaldehyde, odorous gases, etc.). Conventional air purification technologies include media filtration, electrostatic precipitator, ultraviolet sterilization, and so on. There are more or less deficiencies in these technologies, such as frequent replacement and high pressure drop for media filtration.

With the mission of air purification solutions with high filtration efficiency, easy maintenance and low operating energy consumption, our company has invested decades of research and development in air purification technology. BPI-Cyclone air purification solutions are becoming more and more perfect, and the system performance is more advanced, stable and reliable.

Nature has a good self-purification function, air ions are nature's air cleaning method. In the most pristine environments, there are naturally higher ion levels. There are higher levels of ions while the air quality is purer. Ion levels fall as we enter into more populated and polluted environments. It may be the easiest air purification solution to transport the ions in nature into the building HVAC system and complete the air purification function before the ions disappear.

Ionization is nature's air cleaning process. Our BPI-Cyclone Air Purification System simulates the self-purification process that occurs in nature. It integrates the air purification technologies of air ionization, axial cyclone separation, electrocoagulation, and electrostatic capture. The products have obtained a number of chinese patents and PCT international patents, patent numbers: ZL 2015101739354, 2015202241106, 2019203710937, 202022660889X, etc.

BPI-Cyclone Air Purification System integrates the air purification technologies of air ionization, axial cyclone separation, electrocoagulation, and electrostatic capture. It has the advantages of high purification efficiency, low operating energy consumption, automatic dust collection, and small maintenance workload.

BPI-Cyclone Air Purification Working Principle

BPI-Cyclone Air Purification System consists of a bipolar ionizer (BPI) and an axial cyclone separator (ACS). The bipolar ionizer is arranged in the air inlet side of the axial cyclone separator. The bipolar ionizer (bipolar ion tubes) produces positively and negatively charged air ions. These air ions actively attract, bind, and neutralize all types of pollutants from the air when the air passes through the dielectric barrier (bipolar ion tubes), and the dust, bacteria, viruses and other particles suspended in the air are charged with positive and negative charges. Then the air flows into the axial cyclone separator, under the induction of the guide vane at the inlet of the axial flow cyclone, the air rotates along the guide body inside the cyclone, and moves forward in a spiral motion with the action of the external fan. During the process of airflow rotation, the particles charged with positive and negative charges collide and agglomerate under the action of electrostatic attraction and centrifugal force, and gain from small size (such as PM2.5) into large size, or ultrafine particles adhere to large particles.

The outer cylinder of the axial cyclone is conductive and is connected to the grounding end of the power supply. The larger agglomerated particles move to the inner wall of the cyclone with the action of centrifugal force and electrostatic attraction, and move forward spirally along the inner wall of the cyclone to the end of the axial cyclone. At the end outlet, they are trapped and dropped into the dust channel, and finally collected by the bottom dust collection box. The clean air flows out from the end outlet of the axial cyclone, which is a concentric cylinder with the axial cyclone, and its diameter is smaller than that of the outer cyclone cylinder.

During the above process, bipolar ions negatively affect the DNA of bacteria and viruses, and reduced bacteria and viruses from the air. Bi-polar ionization interacts with the VOC hydrocarbon chain and breaks down it's structure, turning something complex and irritating or toxic into simple elements like CO2 and H2O, the VOC isn't diluted or masked but is broken down and eliminated.

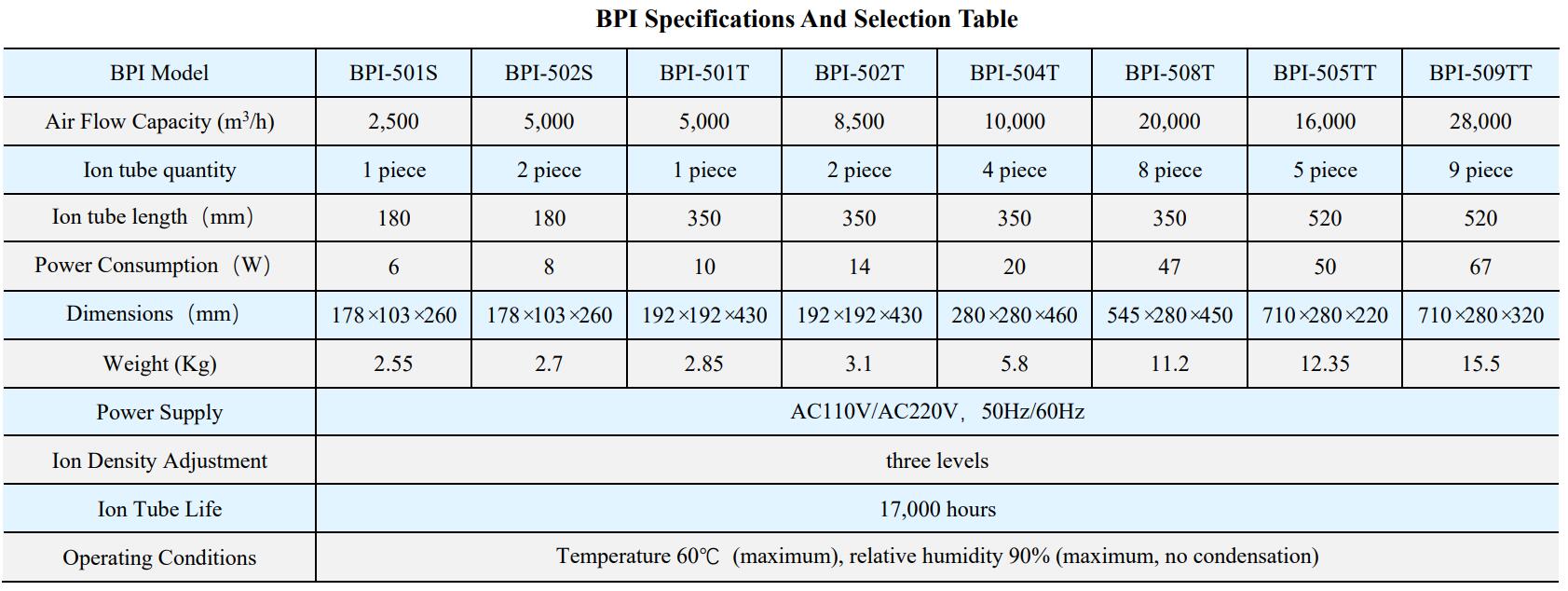

Bipolar Ionizer

The bipolar ionizer (BPI) adopts dielectric barrier ionization technology, the corona electrode is sealed in the plexiglass tube, there is no contact electrostatic danger, and the lower discharge voltage ensures extremely low ozone concentration. When the bipolar ion generator is working, the maximum amount of positive and negative ion generation can reach 2 million pcs/cm3. The electrical box and the ion tube of the bipolar ionizer are connected in a detachable way, which is convenient for maintenance or replacement of the ion tube.

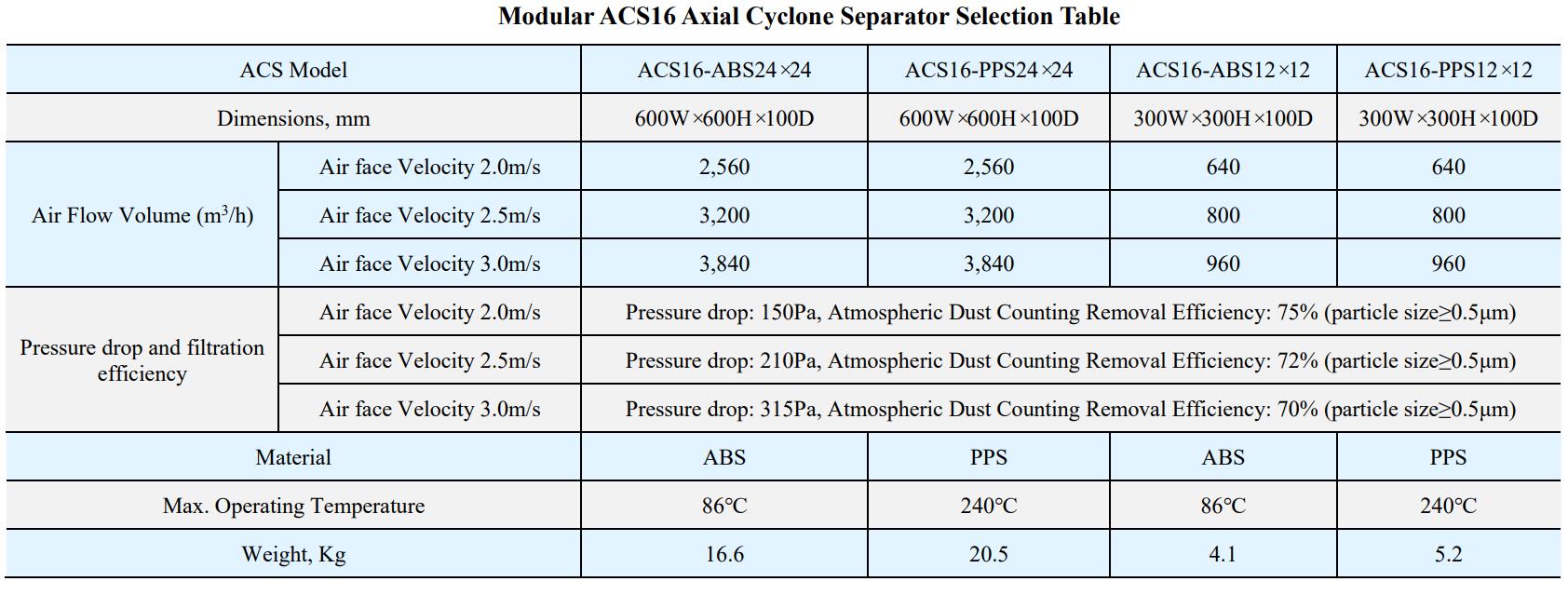

The Axial Cyclone Separator (ACS) adopts patented structure design (patent no. 2015101739354) to ensure the optimization of separation efficiency and operating pressure drop. The axial cyclone separator adopts a modular design, which can be assembled in a certain arrangement and combination according to the treated air volume.

BPI-Cyclone Air Purification System ensures that the ions generated by the bipolar ion generator can quickly achieve air purification in the axial cyclone separator before the ions completely disappear.

Product Advantages:

Integrated air purification technology for efficient removal of suspended particles and VOC gas in the air;

Filtration efficiency: GZ (GB/T 14295-2008), F7 (European standard).

The high-efficiency electrostatic coagulation technology promotes the rapid growth of ultra-fine particles (PM2.5) into large particles, and improve the filtration efficiency of the downstream filter from medium efficiency to high efficiency.

Automatic separation technology of suspended particles from the air, automatic dust collection, avoiding frequent replacement of filters.

The air face velocity is 1.5m/s~3.0m/s, which greatly reduces the installation space compared with the traditional bag dust collector, and is suitable for air handling units.

Constant operating pressure drop, low energy consumption. The operating pressure drop is 100Pa ~ 300Pa (depending on air face velocity).

Equipped with differential pressure sensor, the axial cyclone separator can be used for airflow volume monitoring with accuracy of ±5%.

Modular Axial Cyclone Separator

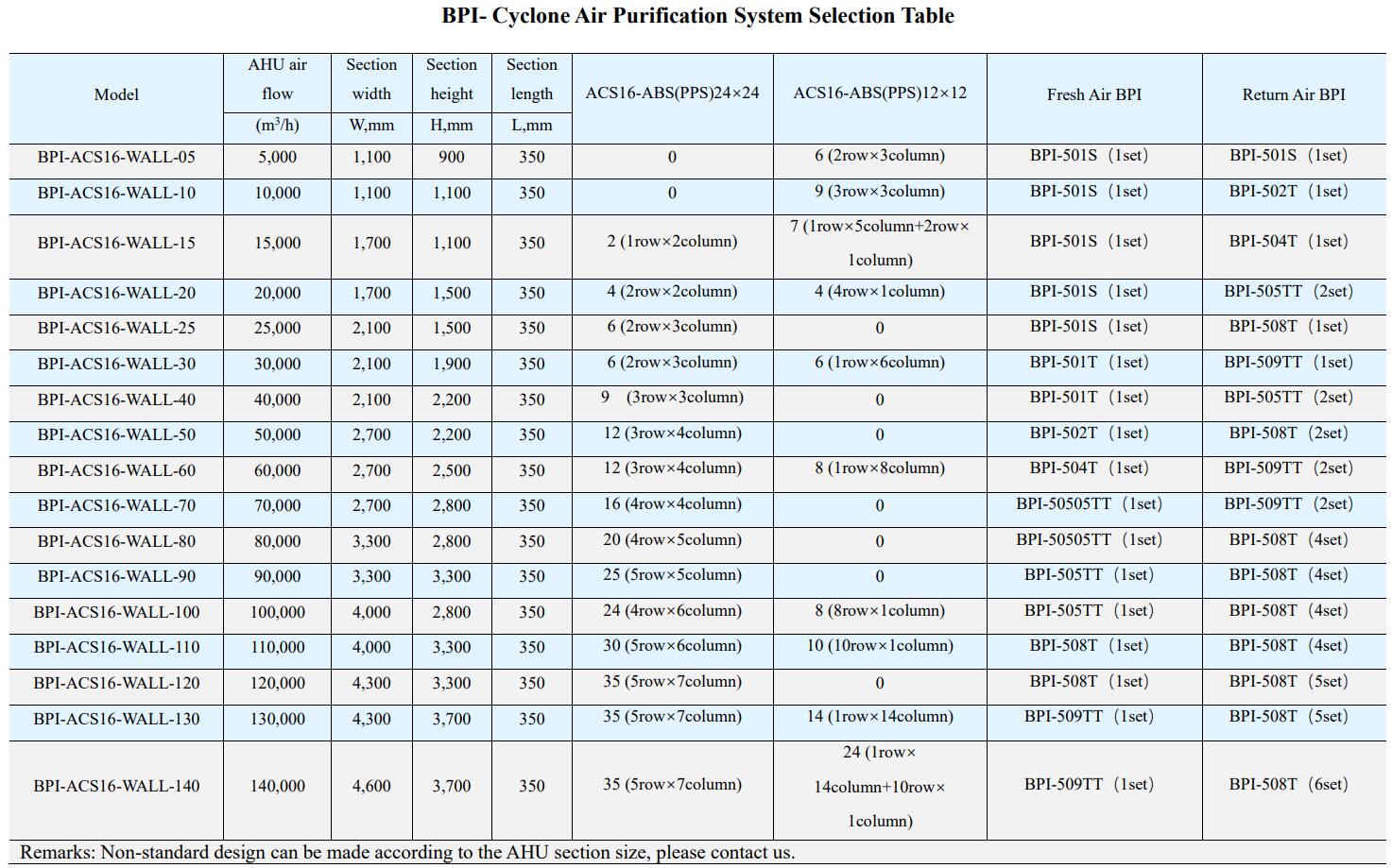

BPI-Cyclone Air Purification System consists of the bipolar ionizer (BPI) and the axial cyclone separator (ACS). The BPI is installed in the air inlet side of the axial cyclone separator.

ACS Axial Cyclone Purification Section

BPI-Cyclone Air Purification System can be applied in the building HVAC system to remove suspended particles and VOC gases from the air, and improve indoor air quality.

The bipolar ionizer can be installed in the fresh air duct and return air duct of the HVAC system, and the axial cyclone separators are installed at the mixing section of the fresh air and the return air in the air handling unit (AHU). According to the AHU's cross-sectional size, several modular axial cyclone Separators are assembled together to form the air purification section. Compared with the traditional air bag filter, BPI-cyclone air purification system integrates the air purification technologies of air ionization, axial cyclone separation, electrocoagulation, and electrostatic capture, so there is no need to frequently replace the filters. The separated particles fall into the dust drawer at the bottom of the axial cyclone purification section, and can be removed manually after running for a period of time.

A medium-efficiency bag filter can be configured on the air outlet side of the BPI-cyclone to further collect low-concentration particles escaped from the BPI-cyclone section. Due to the agglomeration of the ultrafine particles in the BPI-cyclone, the larger particles escaped from the BPI-cyclone section are easily captured by the medium-efficiency bag filter. In this way, The medium-efficiency filter can obtain the filtration efficiency of the high-efficiency filter. As the concentration of particles escaped from the BPI-cyclone section becomes extremely low, the medium bag filter can run for a longer time before reaching the final pressure drop, which greatly reduces the replacement frequency of the bag filter.

Since there is a one-to-one relationship between the airflow volume and the pressure drop passing through the BPI-cyclone section, the BPI-cyclone can also act as an airflow volume monitor.

As the BPI-cyclone air purification system achieves air purification by the integration of centrifugal force and electrostatic attraction, the change of airflow volume will not lead to a significant change in the filtration efficiency for VAV system. When the airflow volume is reduced, the operating pressure drop of the BPI-cyclone section can be reduced.

After passing through the BPI-cyclone section, some positive and negative ions will still remain in the air, which can sterilize and disinfect the downstream heat exchange coils and the inner surface of the air duct, and significantly improve the indoor air quality.

The BPI-cyclone air purification system is equipped with Siemens PLC control panel, and provides standard communication interfaces such as ProfiBus-DP, ProfiNet, ModBus-RTU, etc. for the integration with BAS.

BPI-Cyclone Air Purification System For AHU

This page is a temporarily reserved blank page, if you want to know more details, please contact our company.