ACS Axial Cyclone Purification Section

BPI-Cyclone Air Purification System can be applied in the building HVAC system to remove suspended particles and VOC gases from the air, and improve indoor air quality.

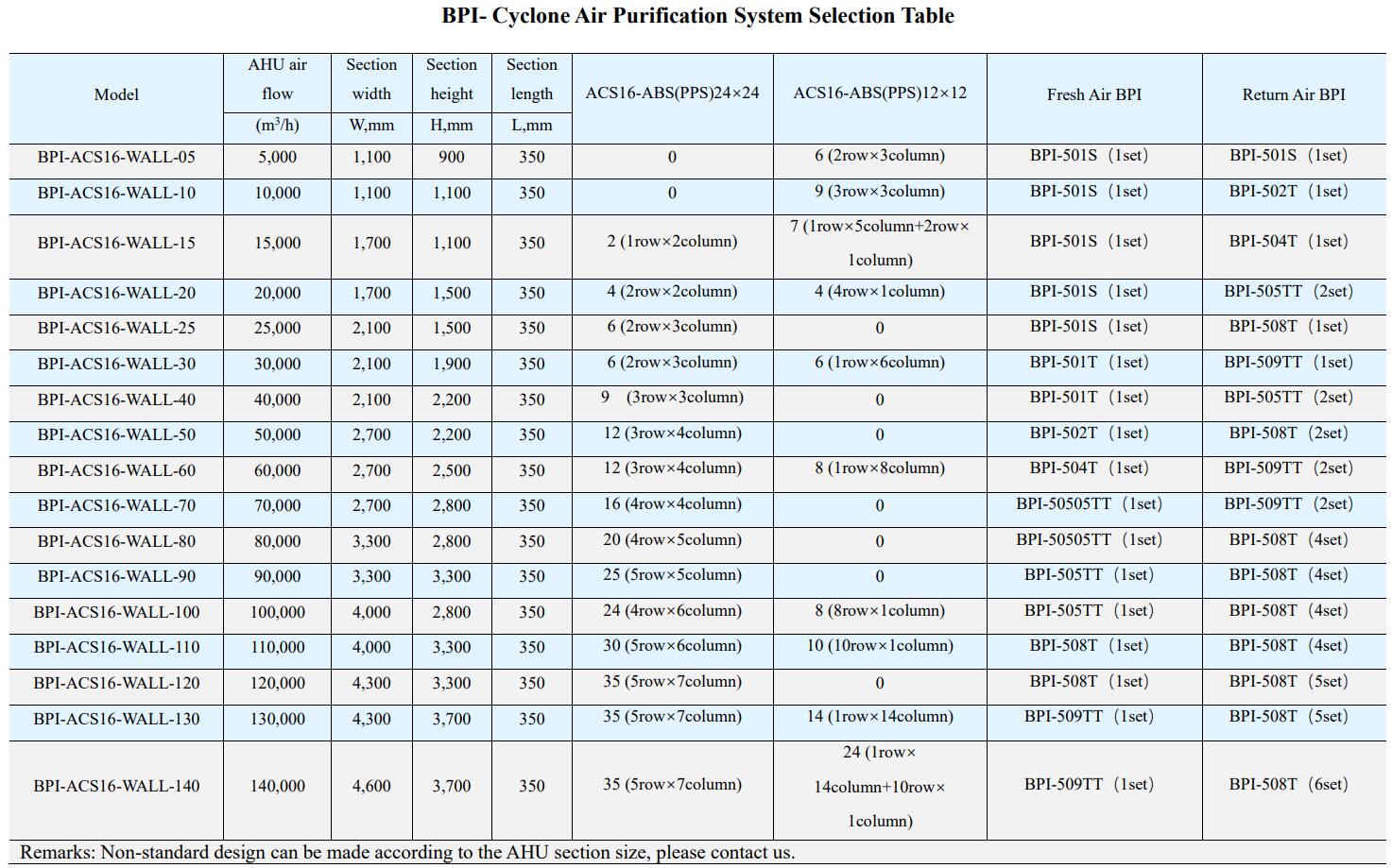

The bipolar ionizer can be installed in the fresh air duct and return air duct of the HVAC system, and the axial cyclone separators are installed at the mixing section of the fresh air and the return air in the air handling unit (AHU). According to the AHU's cross-sectional size, several modular axial cyclone Separators are assembled together to form the air purification section. Compared with the traditional air bag filter, BPI-cyclone air purification system integrates the air purification technologies of air ionization, axial cyclone separation, electrocoagulation, and electrostatic capture, so there is no need to frequently replace the filters. The separated particles fall into the dust drawer at the bottom of the axial cyclone purification section, and can be removed manually after running for a period of time.

A medium-efficiency bag filter can be configured on the air outlet side of the BPI-cyclone to further collect low-concentration particles escaped from the BPI-cyclone section. Due to the agglomeration of the ultrafine particles in the BPI-cyclone, the larger particles escaped from the BPI-cyclone section are easily captured by the medium-efficiency bag filter. In this way, The medium-efficiency filter can obtain the filtration efficiency of the high-efficiency filter. As the concentration of particles escaped from the BPI-cyclone section becomes extremely low, the medium bag filter can run for a longer time before reaching the final pressure drop, which greatly reduces the replacement frequency of the bag filter.

Since there is a one-to-one relationship between the airflow volume and the pressure drop passing through the BPI-cyclone section, the BPI-cyclone can also act as an airflow volume monitor.

As the BPI-cyclone air purification system achieves air purification by the integration of centrifugal force and electrostatic attraction, the change of airflow volume will not lead to a significant change in the filtration efficiency for VAV system. When the airflow volume is reduced, the operating pressure drop of the BPI-cyclone section can be reduced.

After passing through the BPI-cyclone section, some positive and negative ions will still remain in the air, which can sterilize and disinfect the downstream heat exchange coils and the inner surface of the air duct, and significantly improve the indoor air quality.

The BPI-cyclone air purification system is equipped with Siemens PLC control panel, and provides standard communication interfaces such as ProfiBus-DP, ProfiNet, ModBus-RTU, etc. for the integration with BAS.

BPI-Cyclone Air Purification System For AHU